Overview of the Project

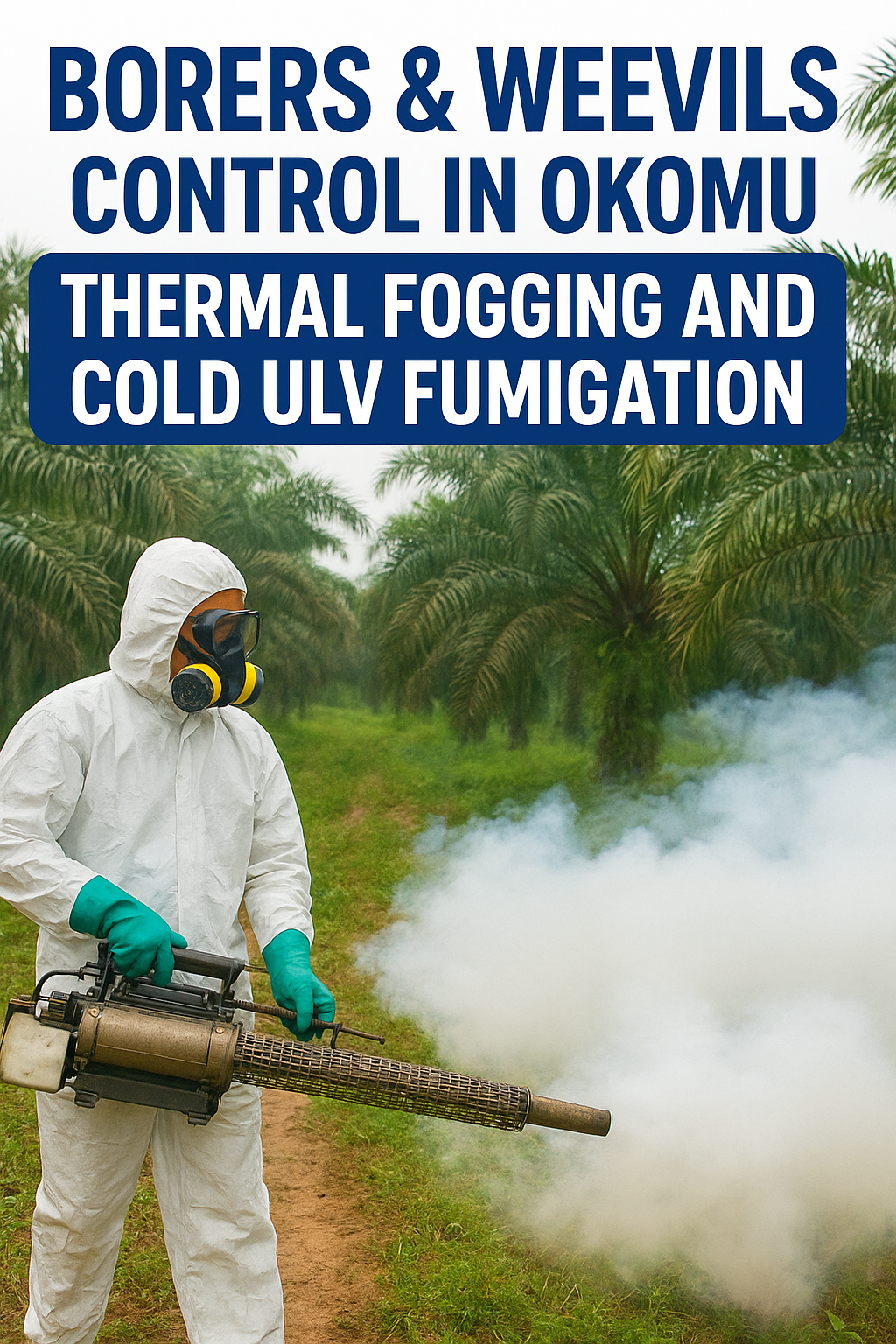

Worldison Pest Control Company recently completed a comprehensive fumigation and pest-eradication project at Okomu, targeting destructive borers, palm weevils, storage pests, and other insect species known for damaging agricultural produce, wood structures, and processing environments. The project demanded a dual-technology approach combining thermal fogging, cold ULV fumigation, residual surface treatment, and environmental monitoring to ensure 100% pest knockdown and long-term protection.

The Okomu environment—rich in palm plantations, processing units, wood facilities, and farm infrastructure—faces constant pressure from insects that thrive in humid, warm climates. Because of this, Worldison deployed a structured and scientifically backed fumigation process involving multiple stages: survey, pest identification, treatment design, chemical selection, application, and post-operation evaluation.

1. Background:

Why the Okomu Fumigation Was Critical

Okomu is a high-output agricultural zone, especially known for palm products, timber, and food processing activities. These operations often attract pests such as:

Palm weevils

Borers

Wood-eating larvae

Flying insects

Stored product pests

Crawling insects inside warehouses and processing areas

Uncontrolled pest outbreaks in such locations can lead to:

Major crop losses

Contamination of food and storage items

Structural damage to wooden frames and processing equipment

Reduced production efficiency

High financial consequences for farm operators

Worldison’s objective was to conduct a full-scale fumigation capable of eliminating both active and hidden pests, including larvae embedded deep inside wood and soil.

2. Pre-Fumigation Assessment

Before the main operation, the Worldison Safety & Fumigation Team carried out:

a. Environmental Inspection

Mapped the affected areas

Identified pest hotspots such as wood piles, silos, processing rooms, and storage facilities

Checked moisture, temperature, and airflow conditions

b. Pest Identification & Classification

Using visual inspections and traps, the team confirmed the presence of:

Palm weevils

Wood borers

Grain beetles

Larval clusters under wooden decks

Flying insect populations around processing sheds

c. Risk & Safety Assessment

To protect staff, nature, and facility workers:

Safety perimeters were established

PPE requirements defined

Chemical hazards evaluated

Evacuation and re-entry time calculated

This assessment guided the technical design of the fumigation.

3. Technologies Used by Worldison Pest Control Company

To achieve maximum pest elimination, the following world-class methods were deployed:

A. Thermal Fogging (High Penetration Method)

Worldison used advanced thermal fogging machines capable of producing ultra-fine, heated droplets that travel deep into:

Wooden structures

Cracks and crevices

High ceilings

Soil layers

Difficult-to-reach compartments

Advantages in Okomu Project

Heat-assisted vapors penetrate deeply

Extremely effective for borers and weevils hiding inside wood

Ideal for large outdoor and semi-outdoor environments

Rapid dispersion over broad areas

B. Cold ULV Fumigation (Ultra-Low Volume Cold Mist)

Cold ULV was used inside processing rooms, storage units, offices, and indoor structures.

Advantages

Produces fine cold mist droplets

Excellent for indoor, enclosed spaces

Fast knockdown of flying and crawling insects

Leaves minimal residue

Safe for sensitive equipment and agro-processing machines

C. Residual Surface Treatment

After fogging, all critical surfaces were treated with WHO-certified residual insecticides to ensure long-term protection.

This step prevents:

Re-entry of pests

Fresh infestation from nearby plantations

Larval re-emergence

D. Environmental Monitoring & Verification

Worldison concluded the operation with:

Air quality testing

Insect trap re-evaluation

Chemical breakdown verification

Safety clearance certification

4. Chemicals & Agents Applied

Worldison selected environmentally responsible and internationally approved pest control agents including:

Synthetic pyrethroids

Organophosphate-based fogging concentrates

Growth regulators (IGRs)

Multi-action borer and weevil eliminators

All chemicals comply with:

WHO standards

NESREA guidelines

NAFDAC regulations

International pest management protocols

5. Step-by-Step Breakdown of the Fumigation Process

Step 1: Area Preparation

Clearing the treatment zone

Isolating sensitive equipment

Covering exposed consumables

Ensuring people and livestock evacuation

Step 2: Thermal Fogging Operation

Machines pre-heated

Fogging chemical introduced

Dense fog deployed across outdoor zones and wooden structures

Monitoring airflow for optimal penetration

Step 3: Cold ULV Fumigation

Indoor rooms sealed

ULV machines set to required microns

Even distribution of mist across surfaces

Focus on ceilings, equipment stands, and dark corners

Step 4: Residual Spraying

Targeted spraying of walls, joints, baseboards, and operational spaces

Long-lasting formula applied

Step 5: Safety Ventilation

All fog allowed to settle

Controlled ventilation started

Indoor air quality examined

Step 6: Final Inspection

No pest movement observed

Wood structures declared safe from active borers

Facility cleared for re-entry

Certificate of fumigation issued

6. Results of the Fumigation Project

The Okomu fumigation achieved:

✔ 100% knockdown of active borers and weevils

Thermal fogging proved extremely effective in reaching wood-inhabiting insects.

✔ A sanitized, pest-free processing and packaging zone

Cold ULV eliminated flying insects and crawling pests within closed environments.

✔ Long-term protection with residual barriers

This reduces future infestation risks.

✔ Safer working conditions for staff and improved product quality

Pest-free operations improve productivity and hygiene.

✔ Compliance with agro-industry safety standards

The facility meets inspection expectations for quality and environmental safety.

7. Why Worldison Remains a Leading Fumigation Company in Nigeria

A. Expertise in industrial & agricultural fumigation

From plantations to factories, Worldison handles complex pest environments.

B. Advanced machines (Thermal & ULV)

High-performance equipment ensures deeper penetration and rapid action.

C. Certified chemicals & trained technicians

All fumigators follow international safety protocols.

D. Compliance with Nigerian and global safety regulations

Worldison maintains full alignment with environmental, occupational, and public health standards.

E. Results-driven approach

Every operation ends with inspection, testing, and certification.

8. Conclusion

The just-concluded fumigation project in Okomu stands as another successful milestone for Worldison Pest Control Company. Through advanced thermal fogging, cold ULV misting, and residual treatment techniques, the team delivered a highly effective, safe, and long-lasting pest eradication result.

This operation reinforces Worldison’s reputation as one of Nigeria’s best fumigation and environmental management companies—trusted by agricultural estates, industrial facilities, government institutions, and private organizations.

No comments yet. Be the first!